MAXIMUM

CHATTER

CONTROL

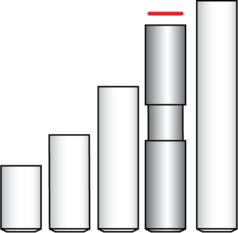

Z-Carb AP | Series ZAP

With conventional end mills, the cutting teeth entering and exiting the material creates a natural rhythm that results in damaging harmonics. Harmonics produce a frequency that resonates through the entire tool, resulting in one of the most damaging forms of cutter wear known as chatter. Chatter degrades the quality of your finish. Until now, your only choice was to adjust your operating parameters to account for the limitations of your conventional end mill. With its patented, one of a kind geometry, the Z-Carb AP offers three stages of chatter suppression, resulting in the quietest, most stable milling experience available.

Features

Rake Geometry

- Variable rake geometry alters and controls the cutting dynamic taking chatter suppression to an unprecedented level.

Long Reach

- Long reach design allows for deeper and faster cuts.

- Unequal helix design changes the cutting angle to improve harmonic.

- Unequal flute spacing helps to disrupt the rhythmic pattern created by the cutting edge helping to suppress damaging harmonics.

- Specialized four flute design is engineered for strength, chip evacuation, and increased productivity over three and four flute end mills.

- The structural design of Ti-Namite-X is adapted to meet a diverse range of applications; everything from high- and low-alloy steels to hardened materials (up to 65 HRC core hardness). Ti-Namite-X is suitable for operations that require high cutting speeds, high temperatures at the cutting edge, and high metal removal rates.

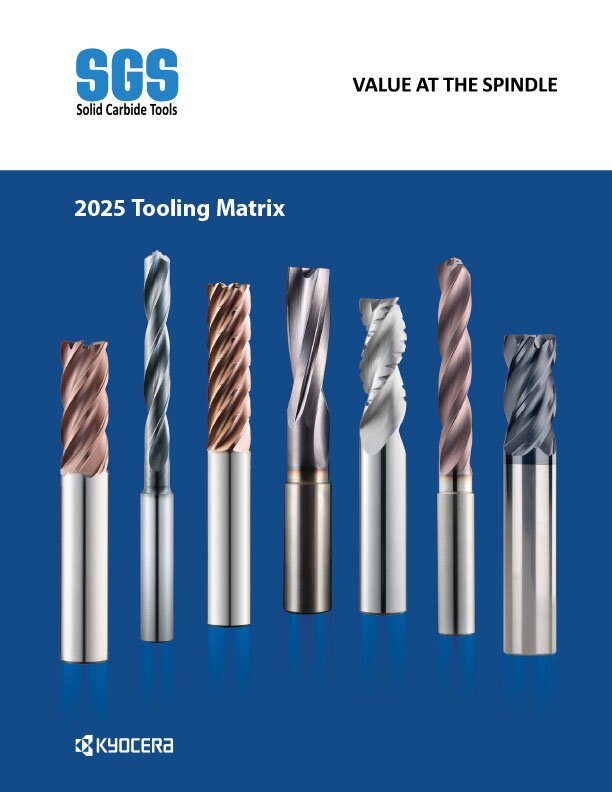

Series Details

Lineup Details

- Cutting Diameter: 1/64" - 1" | 1,0 mm - 25,0 mm

- Length of Cut: 1/32" - 1-1/2" | 3,0 mm - 38,0 mm

- Overall Length: 1-1/2" - 6" | 57,0 mm - 170,0 mm

- Shank Diameter: 1/8" - 1" | 6,0 mm - 25,0 mm

- Corner Radius: 0.002 - 0.125" | 0,1 mm - 6,0 mm

- Coating(s): Ti-NAMITE®-X

- Special Options: Internal Coolant, Weldon Flat, Chip Breaker

Primary Material Applications

- Steel ≤ 45 HRc

- Stainless Steel ≤ 45HRc

- Cast Iron ≤ 45HRc

- High Temp Alloys

- Titanium Alloys ≤ 45 HRc

Industry Applications

Aerospace

Medical

Power Generation

Automotive

Mold & Die

Casting & Foundries

General Engineering

Firearms

Secondary Material Applications

- Cast Iron ≥ 45 HRc

- Hardened Steels < 45 HRc

Resources

SALES SUPPORT

Need help with an application or require sales assistance? Our field sales engineers can help you find the right solution for the job.

WHERE TO BUY

SGS products are sold through an extensive global network of exceptional distribution partners.