KYOCERA SGS

PRECISION TOOLS

KYOCERA SGS Precision Tools

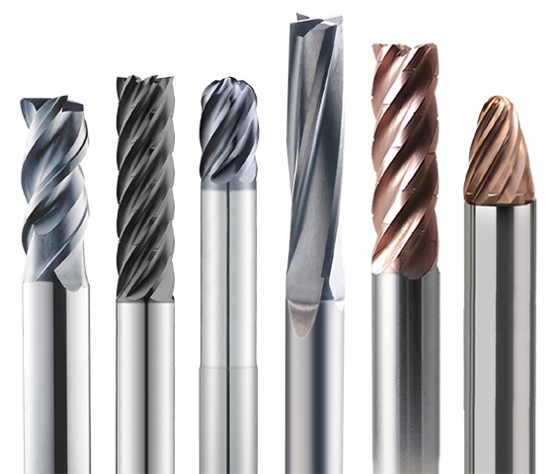

KYOCERA SGS Precision Tools (KSPT) is a manufacturer of world class solid round carbide cutting tools and provides machining solutions and services to a variety of industries, including aerospace, automotive, medical, power generation, mold & die, casting & foundries, general engineering, and firearms.

KSPT actively maintains a serious customer commitment to providing Value at the Spindle®. Whether your value is measured in terms of cost savings, time savings, or ease of use, our solutions consistently deliver results. We take great pride in our customers' success which continually fuels our innovation and next level cutting tool technology performance.

U.S. Facilities

Manufacturing Excellence

Our state of the art manufacturing and warehouse facilities have the capacity and processes to meet the quality and delivery demands of customers in all markets around the world. Complete inspections performed within its metallurgical lab and manufacturing quality departments ensure the use of high quality carbide and reliable manufacturing consistency regardless of when a cutting tool is produced.

Research and Innovation

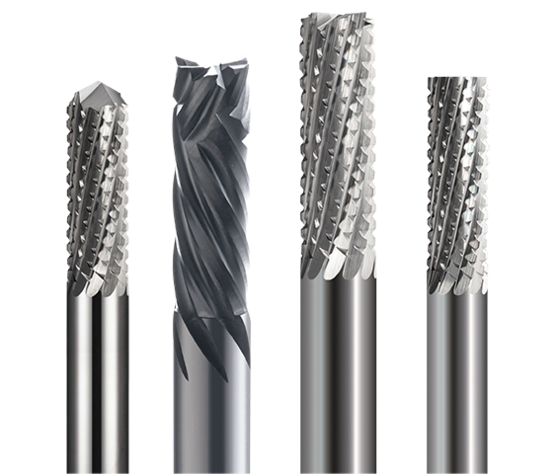

We are proud to have pioneered some of the world’s most advanced cutting technologies due to rigorous testing of tools, coatings, and materials within its Global Innovation Center. It is this commitment to innovation that has launched patented products and technologies like the Z-Carb with its variable geometry and cutting edge preparation, Series 43 APR® and APF® ultra high performance aluminum cutting tools, and the JetStream coolant technology.

Innovative Coating Technology

Our proprietary tool coatings extend tool life and improve performance, influencing critical machining parameters. We lead in developing material and tool-specific coatings through in-house groups in North America and Europe.

Learn More

Fast and Efficient Logistics

We've streamlined our logistics for your convenience, making it easier than ever to access our products. With millions of dollars invested around the world on warehouse automation, packaging and labeling, and valuable logistics partnerships, everything is subject to our stringent quality controls to deliver world class products to you on time.

Regrinding and Value Maximization

SGS is committed to providing superior tooling services in the areas of Reconditioning, Recoating, Regrinding, Specials and Alterations. These services are offered to provide unique solutions and enhanced tool life with involvement from the SGS Technical Support Team.

Learn More

HIGH PERFORMANCE

MACHINING SOLUTIONS

SALES SUPPORT

Need help with an application or require sales assistance? Our field sales engineers can help you find the right solution for the job.

WHERE TO BUY

SGS products are sold through an extensive global network of exceptional distribution partners.