STABLE

MOLD & DIE

MACHINING

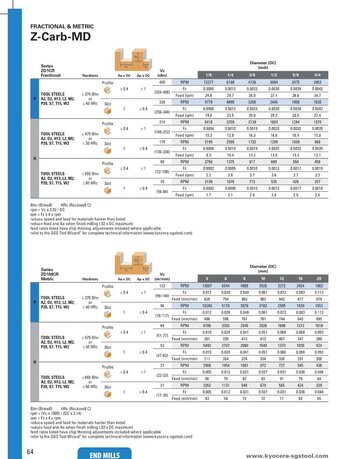

Z-Carb MD | Series ZD1

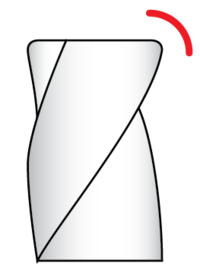

The patented unequal high helix of the Z-Carb MD reduces damaging harmonics by changing the angle at which each cutting edge enters and exits the material. Combined with unequal flute spacing and a heavy core, this end mill effortlessly machines hardened steels with incredible tool life.

Features

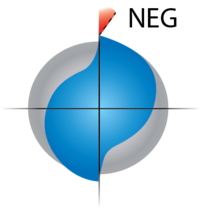

Rake

- The original Z-Carb design with a negative rake, heavy core, and higher helix for strength and shearing of hard mold & die materials.

Corner

- Enhanced corner geometry with tight tolerance corner radii.

Fluting

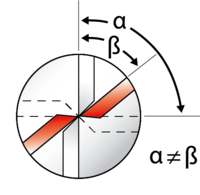

- Unequal flute spacing helps to disrupt the rhythmic pattern created by the cutting edge helping to suppress damaging harmonics.

Coatings

- The structural design of Ti-Namite-X is adapted to meet a diverse range of applications; everything from high- and low-alloy steels to hardened materials (up to 65 HRC core hardness). Ti-Namite-X is suitable for operations that require high cutting speeds, high temperatures at the cutting edge, and high metal removal rates.

Series Details

Lineup Details

- Cutting Diameter 1/8"-3/4" | 3,0 mm - 20,0 mm

- Length of Cut 5/32"-15/16" | 4,0 mm - 24,0 mm

- Overall Length 2 1/2"-5 1/2" | 57,0 mm - 104,0 mm

- Shank Diameter 1/4"-3/4" | 6,0 mm - 20,0 mm

- Reach 1/2"-3 1/4" | 15,0 mm - 55,0 mm

- Corner Radius .010 - .060 | 0,20 mm - 2,0 mm

- Coating(s) Ti-NAMITE-X

Primary Material Applications

- Cast Iron ≥ 45 HRc

- Hardened Steels ≤ 65 HRc

Industry Applications

Aerospace

Medical

Power Generation

Automotive

Mold & Die

Casting & Foundries

General Engineering

Secondary Material Applications

- Steel ≤ 45 HRc

- Cast Iron ≤ 45HRc

Resources

SALES SUPPORT

Need help with an application or require sales assistance? Our field sales engineers can help you find the right solution for the job.

WHERE TO BUY

SGS products are sold through an extensive global network of exceptional distribution partners.