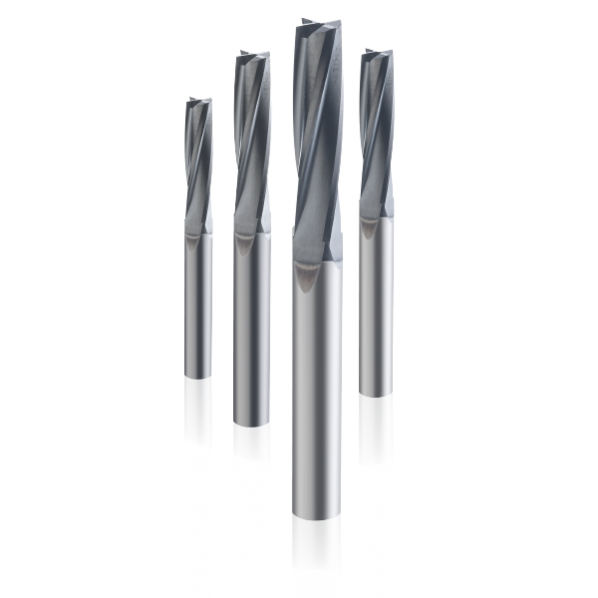

ENGINEERED

SLOW HELIX

FOR ABRASIVE MATERIALS

Series 27

Slow helix design adds strength to the edge allowing easy milling of highly abrasive materials. Available with Di-NAMITE diamond coating. Di-NAMITE is the hardest coating available with the best abrasion resistance.

Features

Helix

- Slow helix design adds strength to the edge allowing ease for milling highly abrasive materials.

- Two levels of chatter suppression: variable helix and indexing.

- This rigid design of a slow helix is complimented with a variable helix to help reduce vibration and deflection.

Flute

- Four flute end mill series engineered for machining non-ferous materials.

Design

- The stable configuration and full cutting-edge leads to improved surface finishes.

- Excels at roughing (slotting, profiling) and finishing in a variety of plastics and composites.

- The design creates a short path for material evacuation during machining.

- Balanced geometry reacts positively to address the complexity of the composite fiber matrix.

Coatings

- This is the hardest coating available with the best abrasion resistance. It is carbon based so it is limited in application capabilities. This coating is suitable for machining highly abrasive, non-ferrous materials such as CFRP and graphite.

Series Details

Lineup Details

- Cutting Diameter: 1/4"-3/4" | 6,0 mm - 16,0 mm

- Length of Cut: 1"-1 3/8" | 25,0 mm - 48,0 mm

- Overall Length: 2 1/2"-4" | 63,0 mm - 115,0 mm

- Shank Diameter: 1/4"-3/4" | 6,0 mm - 16,0 mm

- Coating(s): Uncoated, Di-NAMITE

Primary Material Applications

- Plastics / Composites

Industry Applications

Aerospace

Medical

Power Generation

Automotive

Mold & Die

Casting & Foundries

General Engineering

SALES SUPPORT

Need help with an application or require sales assistance? Our field sales engineers can help you find the right solution for the job.

WHERE TO BUY

SGS products are sold through an extensive global network of exceptional distribution partners.