PRECISION

PICATINNY

MACHINING

Picatinny Rail Tools

The new Picatinny Rail Tools are meticulously engineered for applications in the firearms industry. These tools are divided below by application and material.

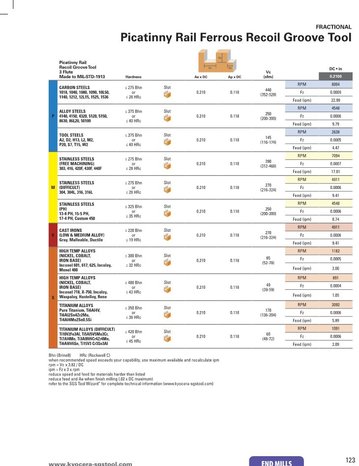

Ferrous Recoil Groove Tool

Equipped with a heavy core design for rigidity in difficult-to-machine materials, the tools are ideal for work in steels, stainless steels, hardened steels and titanium. The specially engineered flute design adds strength and improves chip flow and the tight corner radius tangency tolerance makes this an ideal tool for machining quality recoil grooves.

Features

- Open Flute design improves chip removal at high feed rates

- Specially engineered flute shape for improved chip control

- Circular land improves surface finish and chatter suppression

- Symmetrical end gashing improves balance in high-speed operations

- Meets MIL-STD 1913

Non-Ferrous Recoil Groove Tool

The 3 flute open design improves chip removal at high feed rates. The Symmetrical end gashing improves balance in high-speed operations and the Ti-Namite-B coating makes the tool ideal for slotting operations in non-ferrous materials.

Features

- Open Flute design improves chip removal at high feed rates

- Circular land improves surface finish and chatter suppression

- Symmetrical end gashing improves balance in high-speed operations

- 45 degree chamfer enables slot and deburr in one operation

- Meets MIL-STD 1913

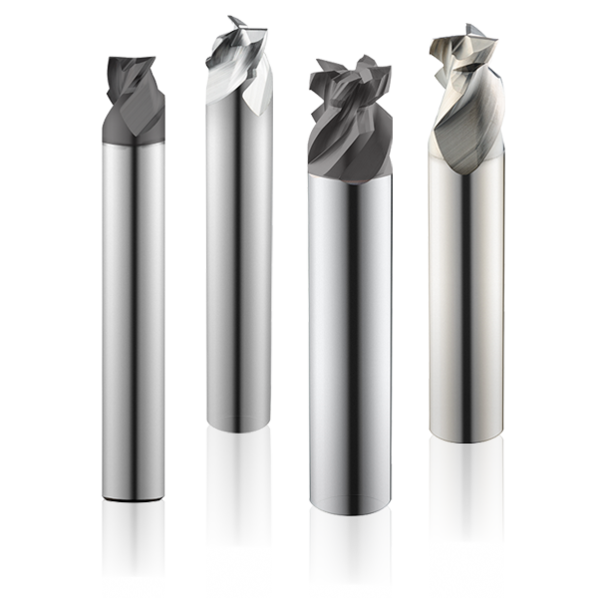

Ferrous Dovetail Form Tool

The Five Flute open endwork design allows for increased chip space with higher machining parameters. The tools are ideal for work in steels, stainless steels, hardened steels and titanium.

Features

- The five-flute design allows for higher machining parameters

- Open-end work design allows for increased chip space

- Square end configuration with enhanced corner strength to improve corner durability

- Meets MIL-STD 1913

Non-Ferrous Dovetail Form Tool

The three-flute open design improves chip removal at high feed rates. The symmetrical end gashing improves balance in high-speed operations and the specially engineered flute shape adds increased chip control.

Features

- Open Flute design improves chip removal at high feed rates

- Specially engineered flute shape for improved chip control

- Circular land improves surface finish and chatter suppression

- Symmetrical end gashing improves balance in high-speed operations

- Meets MIL-STD 1913

Ferrous

Non-Ferrous

Resources

SALES SUPPORT

Need help with an application or require sales assistance? Our field sales engineers can help you find the right solution for the job.

WHERE TO BUY

SGS products are sold through an extensive global network of exceptional distribution partners.