PRECISION

FLAT BOTTOM

HOLEMAKING

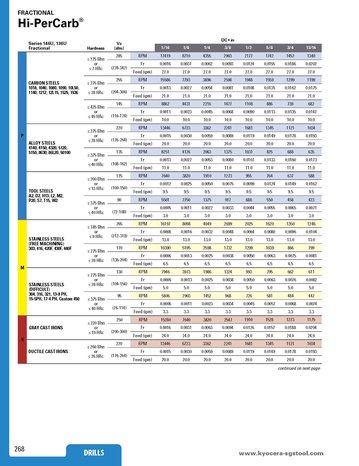

Hi-PerCarb® | Series 146U / 136U

The SGS Hi-PerCarb® Series 146U and 136U flat bottom drills provide a robust solution to a variety of challenging holemaking applications in the automotive, agriculture, oil and gas, and general machining industries. Whether drilling conventionally, on angled or curved surfaces, cross or intersecting holes, unique features of the SGS design combine to produce precise, high-quality holes, with minimal breakout bur.

Features

ECCENTRIC 4-MARGIN DESIGN

- A unique coolant channel design allows repositioning of the trailing margins for improved stability over conventional two and four margin drills

- Eccentric style clearance reduces margin contact with the workpiece without reducing strength

END GEOMETRY

- The primary only relief allows the trailing margins to help stabilize the drill up to three times faster than conventional designs

- High shear corner geometry minimizes exit bur

- Computer controlled edge hone protects against edge chipping in difficult applications

COOLANT CHANNELS

- The two-channel design provides additional coolant in the hole when thru-tool coolant is not available

Coating

Combine to minimize material adhesion and maximize wear resistance in a wide range of workpiece materials.

Series Details

Lineup Details

- Cutting Diameter: 1/8"-13/16" | 3,0 mm - 20,00 mm

- Length of Cut: 9,0 mm - 62,0 mm

- Overall Length: 55,0 mm - 150,0 mm

- Flute Length: 13,0 mm - 93,0 mm

- Shank Diameter: 6,0 mm - 22,0 mm

- Shank Length: 34,0 mm - 52,0 mm

- Coating: Ti-NAMITE®-X

Primary Material Applications

- Steel ≤ 45 HRc

- Stainless Steel ≤ 45HRc

- Cast Iron ≤ 45HRc

- Cast Iron ≥ 45 HRc

- High Temp Alloys

- Titanium Alloys ≤ 45 HRc

- Non Ferrous

- Plastics / Composites

- Hardened Steels < 45 HRc

- Hardened Steels > 55 HRc

Industry Applications

General Engineering

Casting & Foundries

Mold & Die

Automotive

Power Generation

Medical

Aerospace

Firearms

Resources

SALES SUPPORT

Need help with an application or require sales assistance? Our field sales engineers can help you find the right solution for the job.

WHERE TO BUY

SGS products are sold through an extensive global network of exceptional distribution partners.