HIGH PRODUCTION

HRSA & STAINLESS STEEL HOLEMAKING

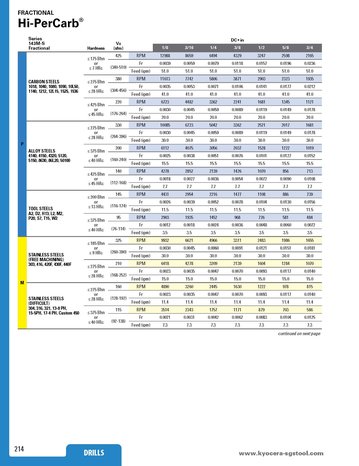

Hi-PerCarb® | Series 143M-S

Hi-PerCarb® Series 143M-S features a coolant-through design, optimizing coolant flow to enhance tool longevity and aid in efficient chip evacuation. It is available in various designations (fractional, metric, decimal, number, and letter) with 3XD and 5XD lengths of cut. The drill is equipped with advanced features like eccentric single margin design to reduce frictional heat and minimize material adhesion.

Features

ECCENTRIC 2-MARGIN DESIGN

- Reduces frictional heat and minimizes material adhesion to the margins without weakening the drill

- Lower contact with the hole surface improves hole finish and quality, especially in gummy workpiece materials

POINT DESIGN

- Stabilizes on contact for exceptional hole size and cylindricity

- Low thrust force reduces machine power requirement and extends tool life

- Computer controlled edge hone protects against chip damage

COOLANT THROUGH DESIGN

- The modified coolant hole exit increases flow for improved chip evacuation and extended tool life

Coating

Provides exceptional wear and erosion resistance when drilling heat resisting alloys like Inconel, stainless steel, and titanium.

Series Details

Lineup Details

- Cutting Diameter: 1/8"-3/4" | 3,0 mm - 19,05 mm

- Length of Cut: 36,0 mm - 50,0 mm

- Overall Length: 62,0 mm - 153,0 mm

- Flute Length: 20,0 mm - 101,0 mm

- Shank Diameter: 6,0 mm - 20,0 mm

- Coating: Ti-NAMITE®-A

Primary Material Applications

- Stainless Steel ≤ 45HRc

- High Temp Alloys

- Titanium Alloys ≤ 45 HRc

Industry Applications

General Engineering

Casting & Foundries

Mold & Die

Automotive

Power Generation

Medical

Aerospace

Firearms

Secondary Material Applications

- Steel ≤ 45HRc

- Cast Iron ≥ 45 HRc

- Non-Ferrous

Resources

SALES SUPPORT

Need help with an application or require sales assistance? Our field sales engineers can help you find the right solution for the job.

WHERE TO BUY

SGS products are sold through an extensive global network of exceptional distribution partners.