ENGINEERED

FOR

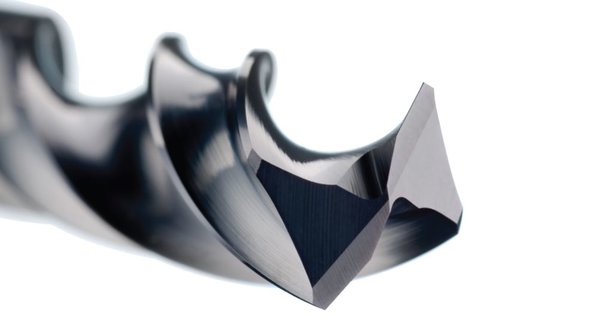

EDGE PROTECTION

Hi-PerCarb® | Series 135

The Series 135 drill features a high-performance flute design that enhances chip transportation and augments strength, enabling aggressive drilling. Furthermore, the drill incorporates a specialized 145° notched point that promotes self-centering, eliminating the need for a spot drill and effectively controlling chips, thus reducing thrust and deflection during drilling.

Features

HIGH PERFORMANCE FLUTE DESIGN

- Efficiently transports chips

- Increases strength for aggressive drilling

- 4-Margin Design improves accuracy and surface finish for increased stability and rigidity

- Secondary Flute improves coolant flow to point reducing friction along the drill body.

SPECIALIZED 145° NOTCHED POINT

- Self centering eliminates need for spot drill and improves chip control decreasing drill thrust and deflection

- Engineered edge protection improves edge strength and reduces edge fatigue allowing for increased feed rates

Coating

Excellent thermal and chemical resistance allows for dry cutting and improvements in performance of carbide. The coating has a high hardness giving great protection against abrasive wear and erosion.

Series Details

Lineup Details

- Cutting Diameter: 1/64"-59/64" | 0,39 mm - 23,41 mm

- Length of Cut: (3XD) 7/64"-4 3/8"

- Length of Cut: (5XD) 5/64" - 2 11/16"

- Overall Length: (3XD) 1 1/2"-7"

- Overall Length: (5XD) 1 1/2"-6"

- Shank Diameter: 1/8"-1"

- Coating: Ti-NAMITE-A

Primary Material Applications

- Steel ≤ 45 HRc

- Stainless Steel ≤ 45HRc

- High Temp Alloys

- Titanium Alloys ≤ 45 HRc

- Hardened Steel < 45 HRc

Industry Applications

Aerospace

Medical

Power Generation

Automotive

Mold & Die

Casting & Foundries

General Engineering

Firearms

Resources

SALES SUPPORT

Need help with an application or require sales assistance? Our field sales engineers can help you find the right solution for the job.

WHERE TO BUY

SGS products are sold through an extensive global network of exceptional distribution partners.