POWERFUL

TROCHOIDAL

MILLING

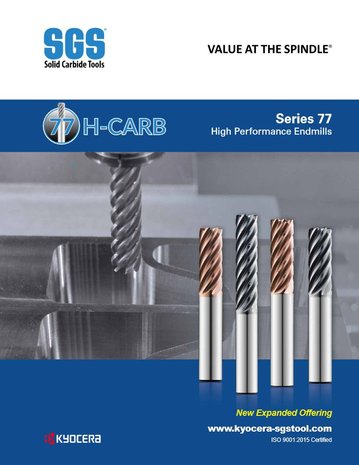

H-Carb | Series 77

The H-Carb 7-Flute High Efficiency end mill specializes in deep axial trochoidal and high-speed machining applications offered at various lengths of cut. The specialized core and flute design improves rigidity and chip flow while reducing deflection. The seven-flute design allows for superior finishes at higher speed and feed rates versus 5 and 6 flute tools. Adding additional benefits to the series is the through-coolant option offering boosted performance and improved chip evacuation.

Features

Through Coolant Options

- The central hole delivers coolant effectively to the cutting zone.

- Enhances chip removal when pocketing or slotting.

Depth of Cut - Deep Pocket Machining

- Available in 3 lengths of cut (2.5xD, 3xD, 4xD).

- Specializes in deep axial trochoidal and high-speed milling applications.

Fluting & Core

- Specialized seven flute design with an optimized core which improves rigidity, chip flow and reduces deflection.

- Chip Breaker design breaks up chips from the long flute length allowing for better chip flow and evacuation in deep pocketing operations.

- Exclusive Ti-NAMITE®-M coating for higher heat resistance to enhance tool life in difficult-to-machine materials like Titanium.

- Available with Ti-NAMITE®-A coating for superior wear, edge build-up resistance and extended tool life in difficult-to-machine materials like Stainless Steel.

Series Details

Lineup Details

- Cutting Diameter: 1/4" - 1" | 6,0 mm - 25,0 mm

- Length of Cut: 5/8" - 4" | 15,0 mm - 100,0 mm

- Overall Length: 2 1/2"-7" | 63,0 mm - 170,0 mm

- Shank Diameter: 1/4"-1" | 6,0 mm - 25,0 mm

- Corner Radius: .015-.120 | 0,3 mm - 4,0 mm

- Coating(s): Ti-NAMITE®-M, Ti-NAMITE®-A

- Special Options: Chip Breakers, Coolant-Through

Primary Material Applications

- Steel ≤ 45 HRc

- Stainless Steel ≤ 45HRc

- Cast Iron ≤ 45HRc

- Hight Temp Alloys

- Titanium Alloys ≤ 45 HRc

Industry Applications

Aerospace

Medical

Power Generation

Automotive

Mold & Die

Casting & Foundries

General Engineering

Resources

SALES SUPPORT

Need help with an application or require sales assistance? Our field sales engineers can help you find the right solution for the job.

WHERE TO BUY

SGS products are sold through an extensive global network of exceptional distribution partners.