COMPOSITE

PERFORMANCE

ROUTERS

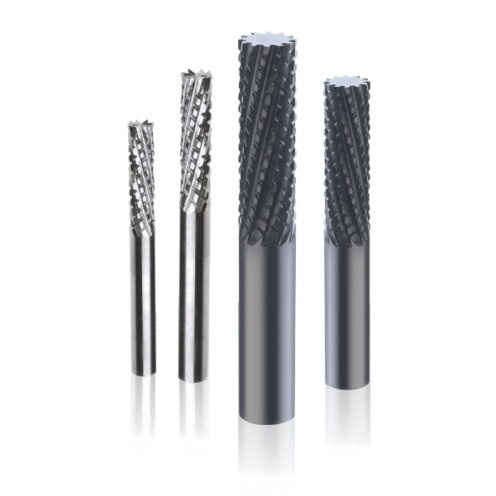

Carbon Composite Routers | Series 20 & 20M

KSPT carbon composite routers were designed for maximum performance in CFRP materials. We partnered with a leading aerospace company to launch the original Series 20, a design focused on trimming and finishing in demanding applications requiring minimal fiber breakout and delamination.

Features

Flutes

- 8-12 flute options are available.

- Multi-flute design and positive geometry to shear with minimal pressure and delamination.

- Left-hand flutes engineered to control the fibers within CFRP, preventing excessive fiber breakout.

Design

- Features chipbreakers for optimal chip removal.

- Unique clearance grind minimizes contact between tool diameter and workpiece eliminating friction.

Coatings

- This is the hardest coating available with the best abrasion resistance. It is carbon based so it is limited in application capabilities. This coating is suitable for machining highly abrasive, non-ferrous materials such as CFRP and graphite.

- This ceramic-based coating ensures a smooth surface and a low affinity to cold welding or edge build-up, which makes it optimal for aluminum and copper applications. It has high toughness and high hardness.

Series Details

Lineup Details

- Cutting Diameter: 1/4"-1/2" / 2,0 mm - 12 mm

- Flute Length: 1"-1 1/2" / 6,0 mm - 38,0 mm

- Overall Length: 2 1/2"-3 1/2" / 38,0 mm - 89,0 mm

- Shank Diameter: 1/4"-1/2" / 3,0 mm - 12,0 mm

- Number of Flutes: 5-12

- End Style: No End Cutting, End Cutting

- Coating(s): Di-NAMITE, Ti-NAMITE-B, Uncoated

Primary Material Applications

- Plastics / Composites

Industry Applications

Aerospace

Medical

Power Generation

Automotive

Mold & Die

Casting & Foundries

General Engineering

Resources

SALES SUPPORT

Need help with an application or require sales assistance? Our field sales engineers can help you find the right solution for the job.

WHERE TO BUY

SGS products are sold through an extensive global network of exceptional distribution partners.